Advantage:

- Precise balance system for hand wheel make it can stop at any position, and the hand-wheel can be quickly locked at top position or any other position.

- Small coarse hand-wheel close to user, easy to operate.

- Quick exchange clamps: paraffin block / universal cassette.

- Knife holder moves sideways for full blade use.

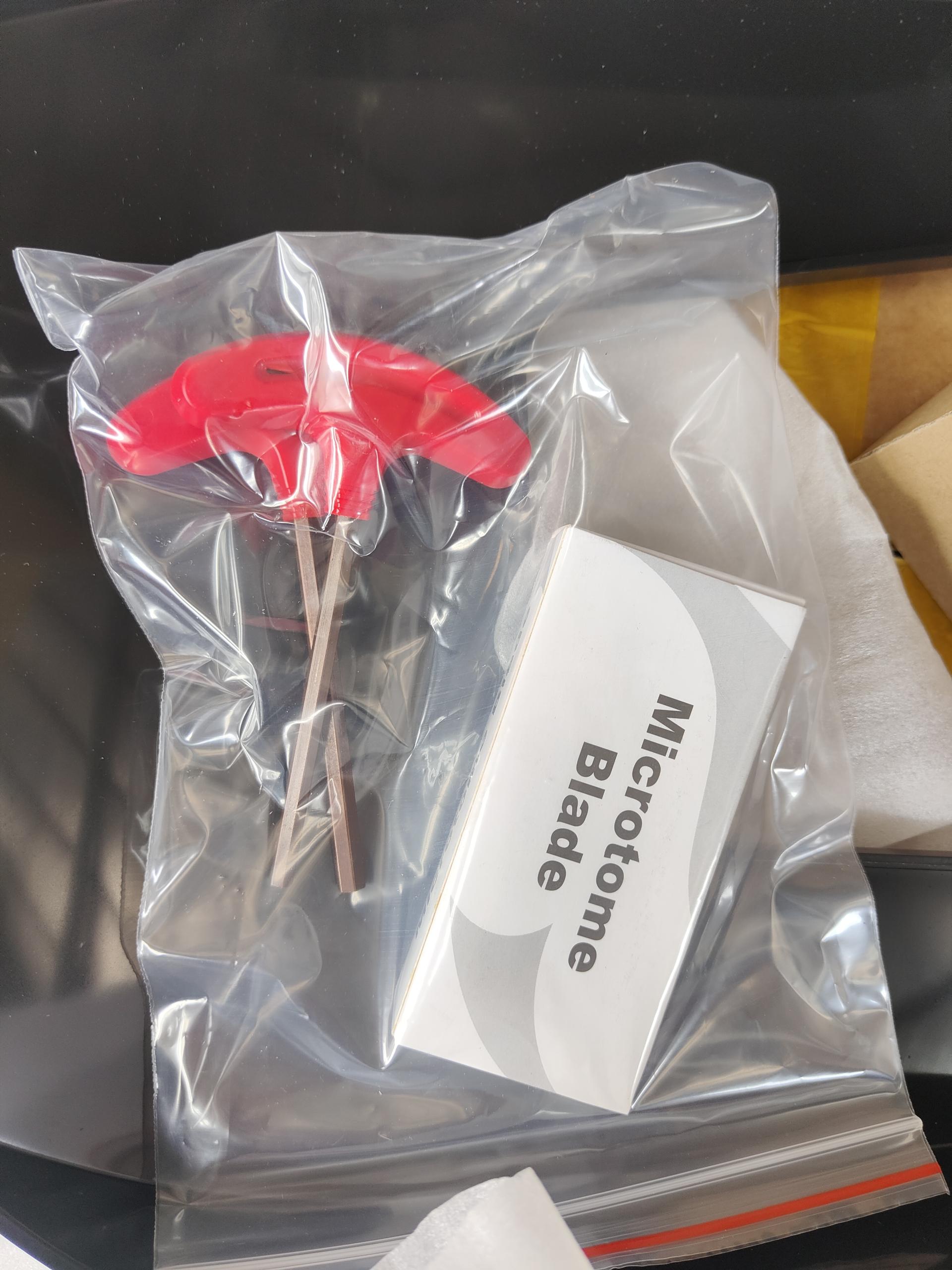

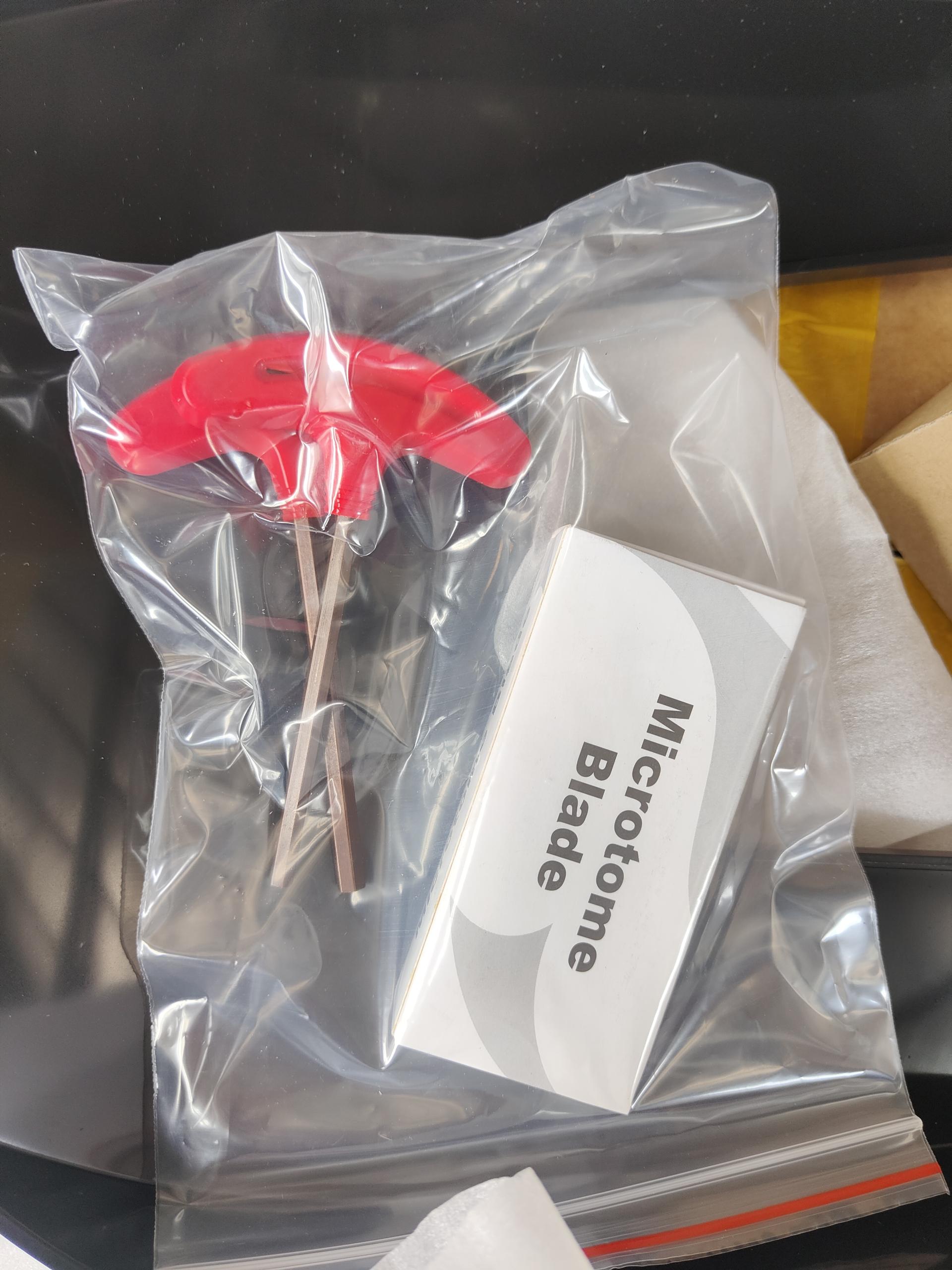

- Red bar on the blade holder covers the whole length for protection and push rod helps to change blade easily.

- Large waste tray, easy to install. Top cover can put with consumables, such as blades, brushs, and specimens etc.

Specification:

| Model |

MT-R2260 |

| Section Thickness Range |

0-60 μm |

| Section Thickness Setting |

0.5–2 μm, in 0.5 μm increments |

| 2–10 μm, in 1 μm increments |

| 10-20 μm, in 2 μm increments |

| 20–60 μm, in 5 μm increments |

| Minimum Section Thickness |

0.5 μm |

| Trimming Thickness Range |

0-60 μm |

| Trimming Thickness Setting |

0.5-2 μm, increment 0.5 μm |

| 2-10 μm, increment 1 μm |

| 10-20 μm, increment 2 μm |

| 20-60 μm, increment 5 μm |

| Precision Error |

±5% |

| Maximum Specimen Size |

60×70 mm |

| Total Horizontal Specimen Feed |

29 mm |

| Vertical Specimen Stroke |

60 mm |

| Movement Range of Blade Holder’s Base |

60 mm (front-to-back) |

| Movement Range of Blade Holder |

23 mm (left-to-right) |

| Specimen Orientation |

X/Y axis 8°, Rotation 360° |

| External Size (W×D×H) |

570×440×290 mm |

| Shipping Size (W×D×H) |

530×620×450 mm |

| N.W./G.W. |

28/40 kg |

Details of Rotary Microtome:

The sleek housing not only enhances the aesthetics but also simplifies the cleaning process, eliminating the need to open it. This design also allows for the convenient placement of consumables.

A protective red bar covering the entire length of the blade holder ensures user safety, and the push bar simplifies blade replacement.

Ergonomically designed to significantly reduce discomfort associated with long hours of operation.

Rotary Microtome FAQ and Solutions

1. Uneven slice thickness

- Blades are dull or not securely mounted.

- Uneven sample hardness or inadequate fixation.

- Worn or contaminated microfeed mechanism (push screw).

- Replace or realign blades to ensure sharpness and secure fixation.

- Optimize sample dehydration and embedding processes to ensure uniform hardness.

- Clean and lubricate the feed mechanism, replacing parts as necessary.

2. Creasing or tearing of slices

- Incorrect blade angle.

- Sample temperature too high (paraffin too soft) or too low (frozen sample partially melted).

- Anti-curl plate (anti-wrinkle sheet) not properly adjusted.

- Adjust the blade tilt angle (usually 4° to 10°).

- Control sample temperature (keep paraffin slices cold, avoid repeated freezing and thawing of frozen slices).

- Calibrate the position of the anti-coil plate to ensure that it is parallel to the blade.

3. Slices self-adhering or failing to form strips

- Incomplete dehydration of the sample (residual moisture or alcohol).

- High ambient humidity or static interference.

- Contaminants on blade or sample surface.

- Reprocess the sample to ensure adequate dehydration transparency.

- Use a dehumidifier or anti-static equipment to keep the lab dry.

- Clean blades and sample surfaces to avoid grease or debris.

Get Social